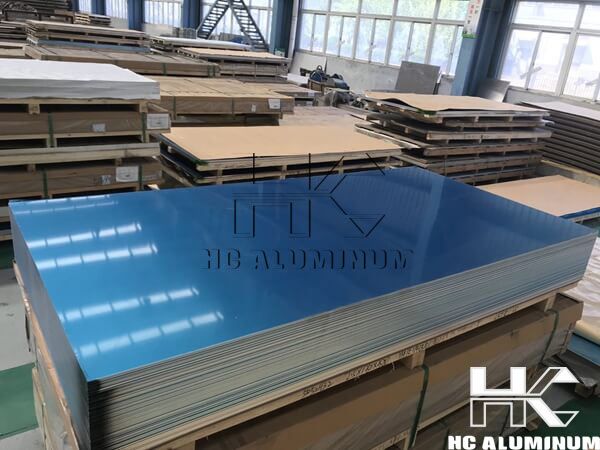

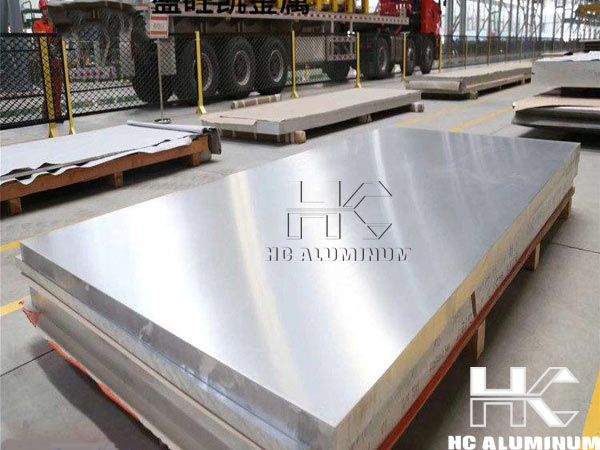

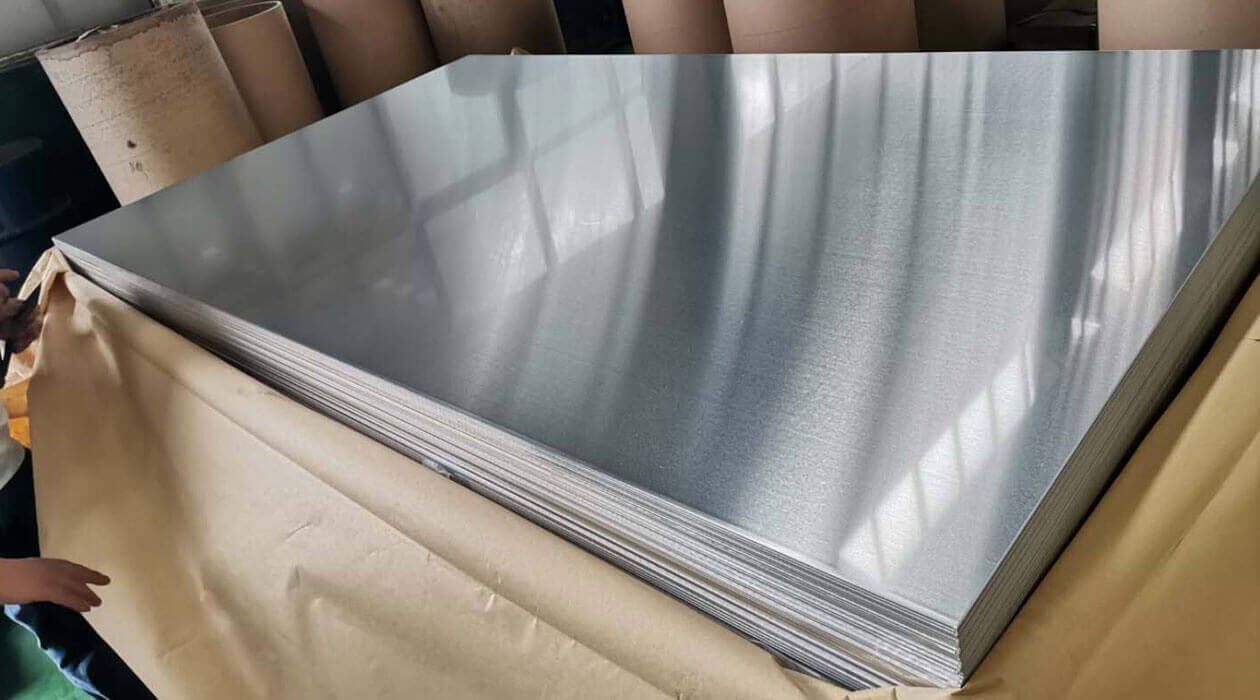

Corrosion Resistant Aluminum Sheet

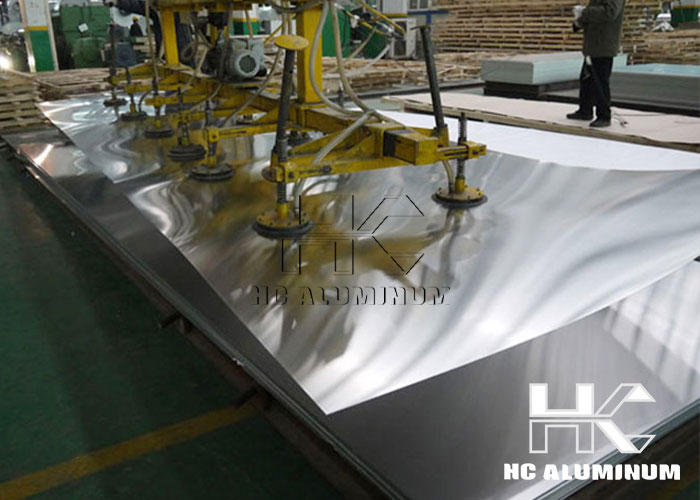

Corrosion resistant aluminum sheet is an aluminum alloy material with excellent corrosion resistance, widely used in construction, shipbuilding, aviation, automotive and chemical industries.

Corrosion resistant aluminum sheet is an aluminum alloy material with excellent corrosion resistance, widely used in construction, shipbuilding, aviation, automotive and chemical industries. Aluminum's inherent corrosion resistance is primarily due to the dense oxide film it forms on its surface, which effectively protects the aluminum from environmental corrosion.

Common corrosion resistant aluminum alloys include the 3000 series, 5000 series and 6000 series. 5000 series aluminum alloys (such as 5052 and 5083) perform particularly well in marine environments and are commonly used in shipbuilding and marine engineering.

1. 3000 series aluminum sheet (such as 3003 and 3004)

Contains manganese as the primary alloying element (content 1.0%-1.5%), it boasts strength approximately 20% higher than pure aluminum, excellent atmospheric corrosion resistance, and good formability, making it suitable for deep drawing and stretching processes.

Applications: Cookware, architectural decorative panels, and chemical equipment linings.

2. 5000 Series Aluminum Sheet (e.g., 5052, 5083)

Maintains magnesium as the primary alloying element (content 3%-5%), boasting strength approaching or exceeding that of mild steel, outstanding seawater corrosion resistance, and excellent weldability.

Applications: Shipbuilding, automotive bodies, pressure vessels, offshore platforms, etc.

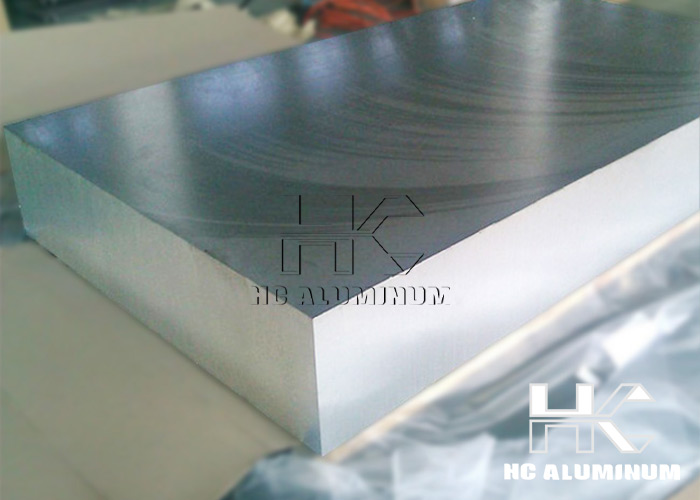

3. 6000 Series Aluminum Sheet (e.g., 6061, 6063, 6082)

Main Composition: Magnesium and silicon as the primary alloying elements (typically containing 0.6%-1.5% magnesium and 0.4%-1.0% silicon).

This aluminum sheet exhibits excellent mechanical properties and corrosion resistance. Its strength can be enhanced through heat treatment, making it suitable for structural parts. Its excellent workability makes it suitable for various processing techniques.

Applications: Widely used in construction, transportation, machinery manufacturing, aviation, and other fields.

Surface-treated corrosion resistant aluminum sheet:

An electrochemical process forms a 5-20μm oxide film on the aluminum surface, significantly improving corrosion and wear resistance. Colors are adjustable (e.g., silver, gold, and black).

Applications: Building curtain walls, electronic equipment housings, decorative components, etc.

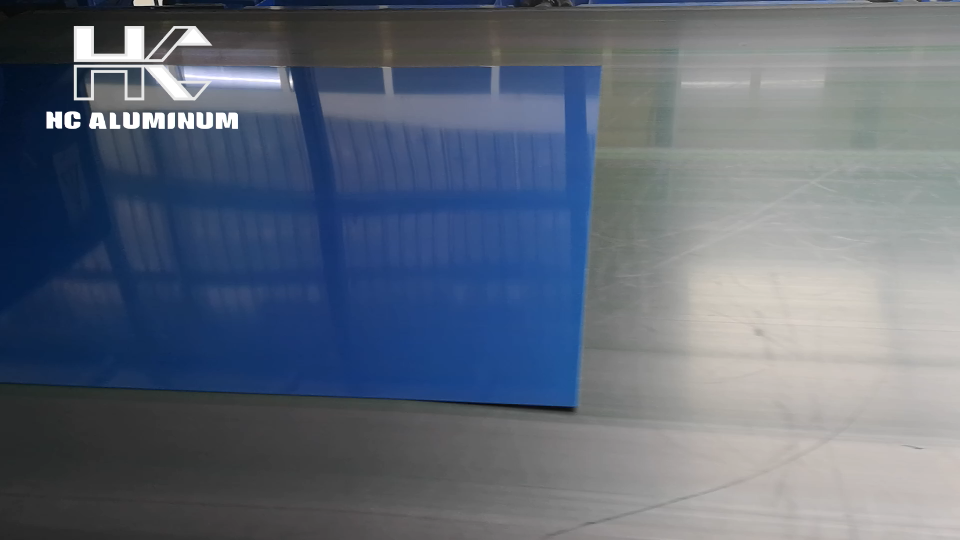

2. Fluorocarbon coated aluminum sheet:

A fluorocarbon coating based on polyvinylidene fluoride (PVDF) offers exceptional weather resistance (up to 25 years without fading) and resistance to acid rain, salt spray, and air pollutants.

Applications: High-end building curtain walls, outdoor billboards, airport terminals, etc.

Key features of corrosion resistant aluminium sheet include:

- Excellent corrosion resistance:

Excellent performance in humid or chemically corrosive environments.

- Lightweight and high-strength:

Aluminum has a low density and high strength, making it suitable for lightweight designs.

- Processability:

Aluminum sheet is easy to cut, weld, and form, making it suitable for a variety of processing techniques.

- Aesthetics:

The aluminum sheet surface can be treated with anodizing, spray coating, and other treatments, creating a variety of appearances.

- Electrical and Thermal Conductivity:

Aluminum has excellent electrical and thermal conductivity, making it suitable for electrical and heat exchange applications.

Application Scenarios of corrosion resistant aluminum sheet:

- Architectural:

Curtain walls, ceilings, interior and exterior decorative panels, etc., utilizing its lightweight, high-strength, corrosion-resistant, and aesthetically pleasing properties.

- Industrial:

Chemical equipment, pressure vessels, pipe linings, etc., requiring long-term resistance to corrosive media such as acids, alkalis, and salt spray.

- Transportation:

Shipbuilding, automobile bodies, aircraft parts, etc., requiring seawater corrosion resistance and lightweight materials.

- Other:

Packaging, printing, and electrical power, such as manufacturing packaging boxes, printed boards, and electronic components.

When selecting corrosion resistant aluminum sheet, consider the characteristics of the three aluminum alloy series based on the specific application requirements, environmental conditions, and mechanical performance requirements. For example, for use in marine environments, the 5000 series aluminum alloy is a better choice; whereas, for applications requiring good weldability and formability, the 3000 series may be more suitable. The 6000 series is suitable for applications requiring higher strength and good workability.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531