Anodized Aluminum Sheet

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531

Product Introduction

Contact Us

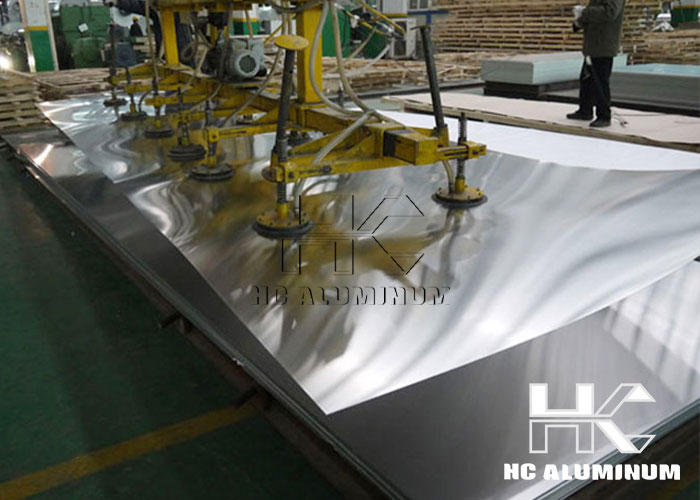

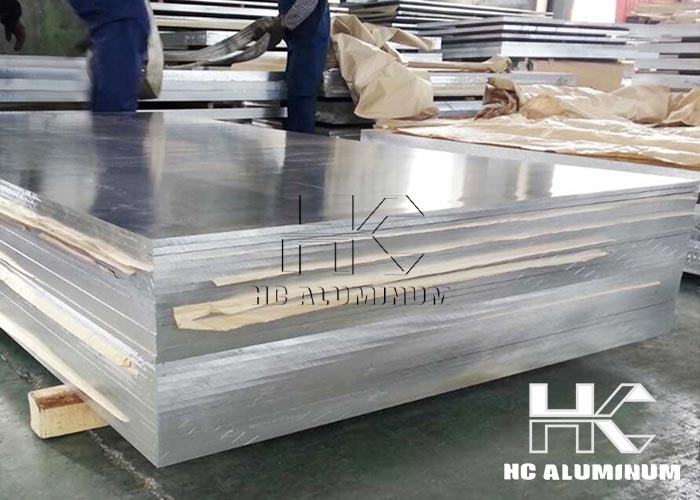

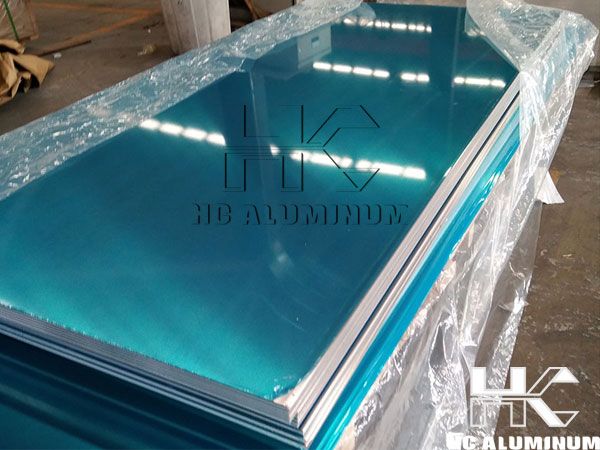

Anodized aluminum sheet is a material made of aluminum oxide (Al2O3) with excellent physical and chemical properties. It is usually based on high-purity aluminum oxide and sintered at high temperatures to form a hard, wear-resistant and corrosion-resistant material.

The anodizing process creates a robust oxide layer on the aluminum surface, enhancing both functional properties and visual appeal.

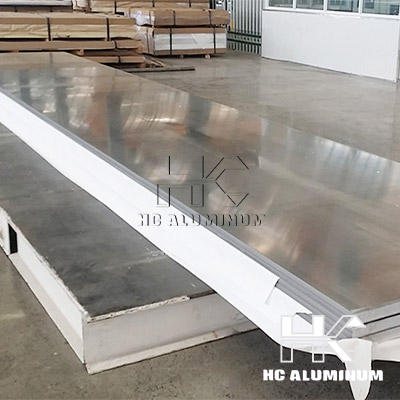

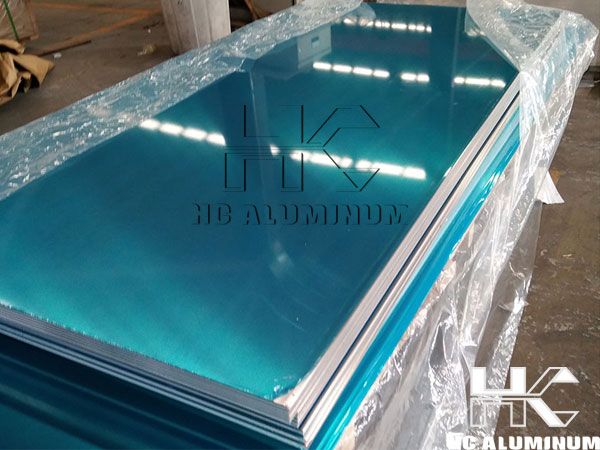

Specification of Anodized Aluminum Sheets:

Product Name | Anodized Aluminum Sheet/Plate/Coil/Strip |

Alloy Series | 1050,1060,1070,1100,3003,3004,3005,3105,5005,5052,5083,5754,6061,6082,8011,etc. |

Temper | O-H112, T3-T8, T351-T851 |

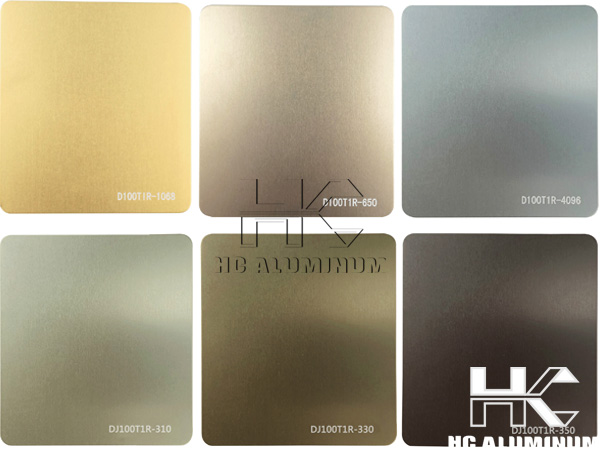

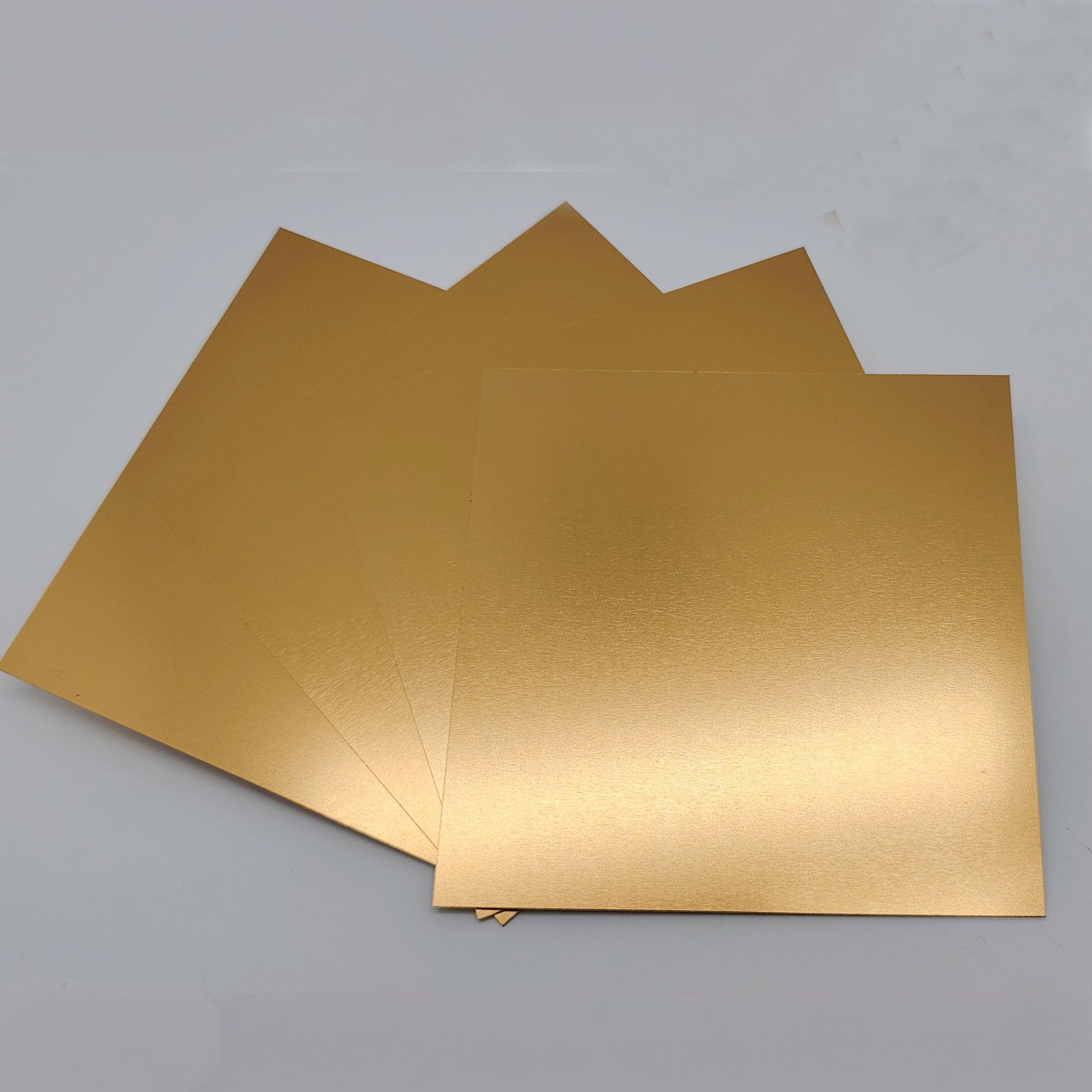

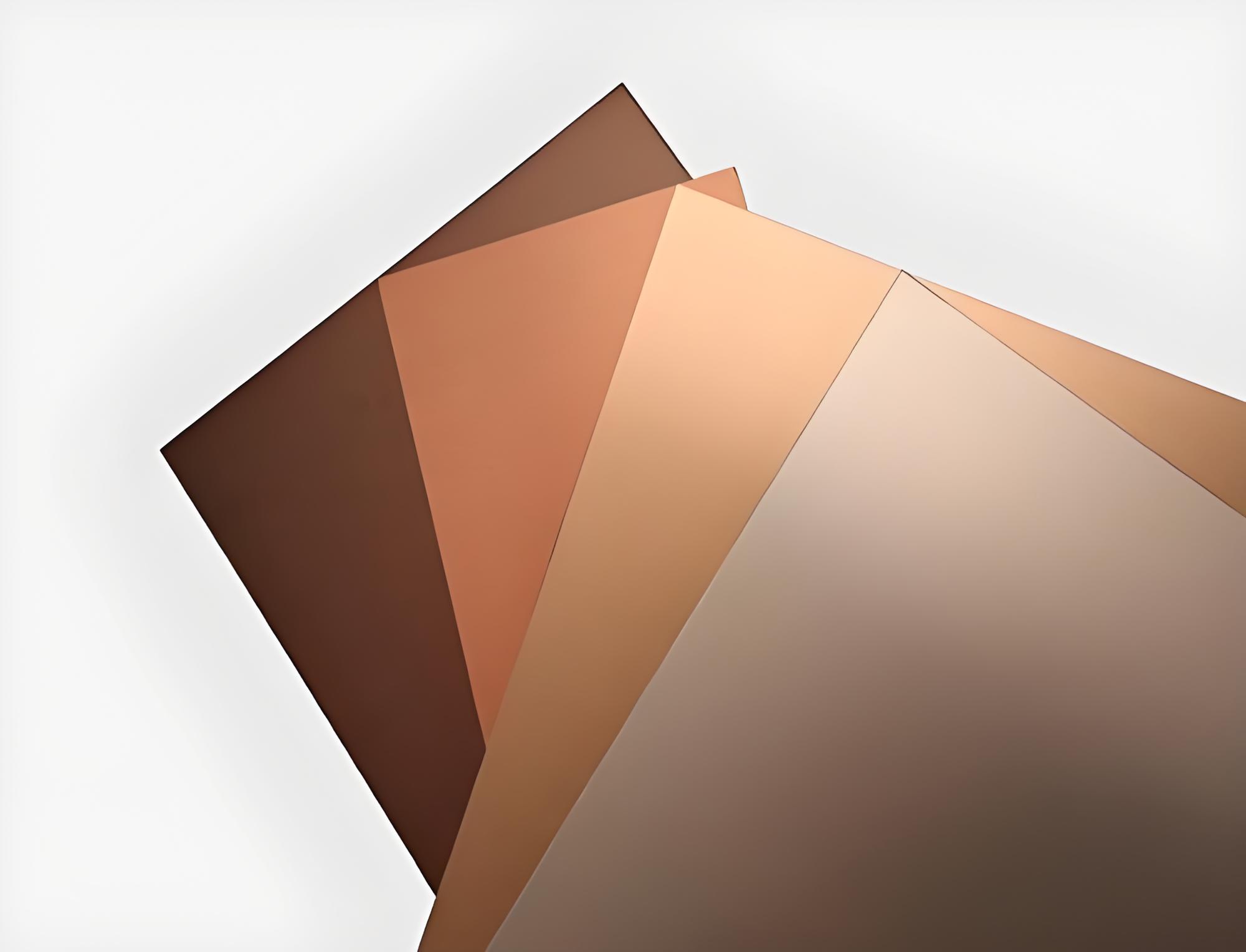

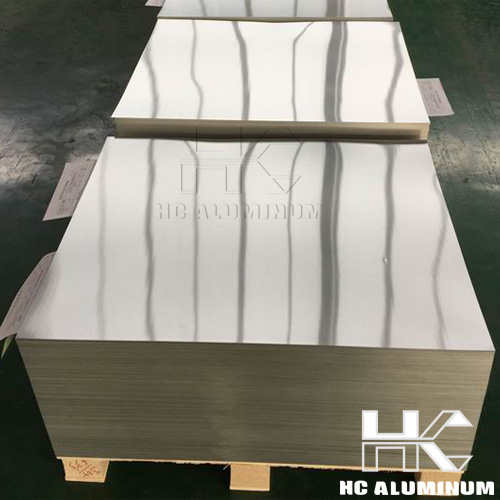

Color Options | Black, White, Blue, Red, Gold, Bronze (Custom hues available upon request) |

Thickness | 0.15mm – 10mm or custom |

Width | Customizable Sizes |

Length | Customizable Sizes |

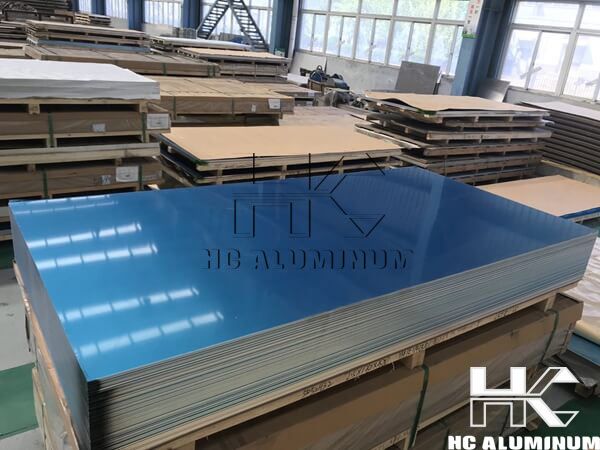

Features of Anodized Aluminum Sheets:

High hardness: Anodized aluminum has a hardness close to that of diamond and has excellent wear resistance.

High temperature resistance: Anodised aluminum can remain stable in high temperature environments and is not easy to deform.

Excellent electrical insulation: Anodized aluminium has good insulation properties and is suitable for electronic components.

Chemical stability: It has good corrosion resistance to most acids and alkalis.

Lightweight: Compared with metal materials, the density of anodized aluminum plates is lower, which is conducive to reducing the weight of the structure.

Application of Anodized Aluminum Sheets:

Electronics industry: Used as an insulating material, it is widely used in circuit boards, substrates of electronic components, etc.

Mechanical parts: Manufacture wear-resistant mechanical parts such as bearings, valves and internal components of pumps.

Medical devices: Due to its biocompatibility, it is suitable for dental restorative materials and orthopedic implants.

Ceramic materials: As the basic material of high-performance ceramics, it is widely used in the manufacture of cutting tools and abrasives.

Aerospace: Used to manufacture lightweight, high-strength structural parts that can withstand extreme environments.

Thermal management: Used in radiators and heat exchangers, it has good thermal conductivity.

Chemical industry: used in chemical reactors and storage tanks, favored for its corrosion resistance.

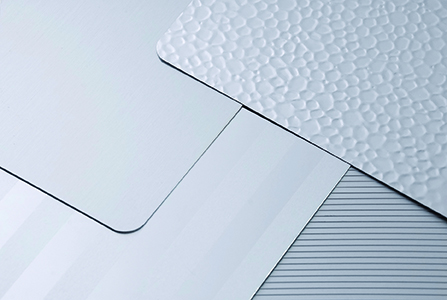

Building materials: used in building facades and interior decoration for beauty and durability.

Optical components: used as lens and window materials in some optical applications.