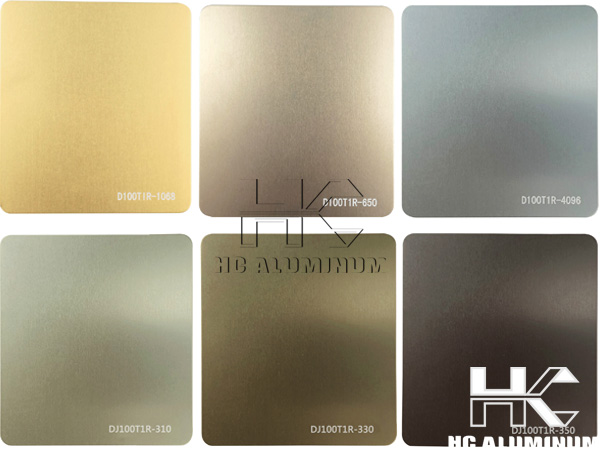

Black Brushed Aluminum Sheet

Black brushed anodized aluminum sheet is a high-performance aluminum material, widely used in precision manufacturing, architectural decoration, and electronics due to its core advantages of combining decorative and functional properties.

Black brushed anodized aluminum sheet is a high-performance aluminum material, widely used in precision manufacturing, architectural decoration, and electronics due to its core advantages of combining decorative and functional properties.

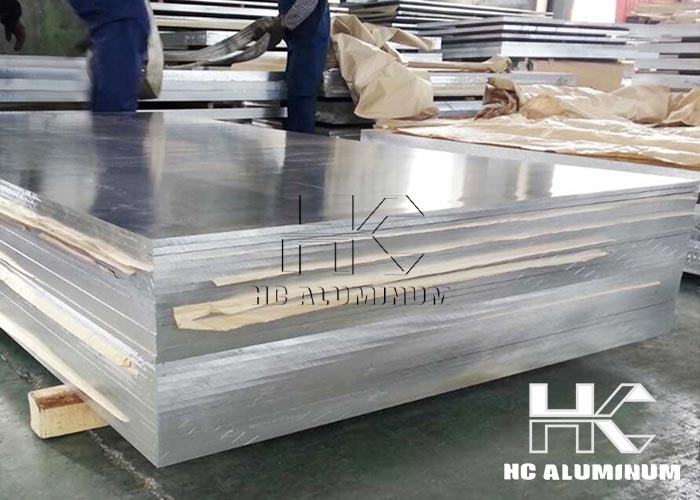

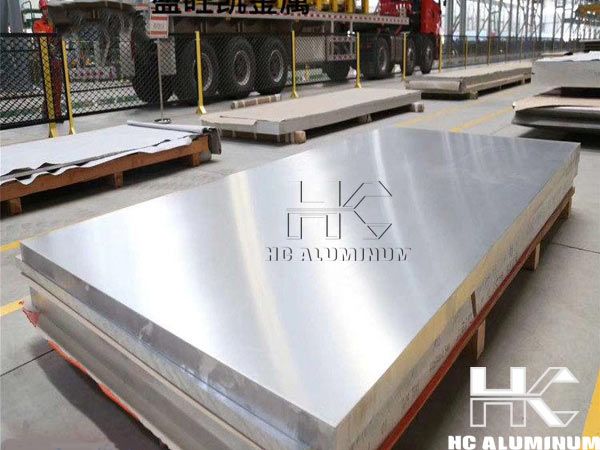

Alloy selection and processing state are crucial prerequisites for determining the basic performance of the black brushed aluminum sheet product. Currently, the mainstream alloys used are 5052 (Al-Mg system) and 6061 (Al-Mg-Si system). These two materials exhibit significant advantages during the anodizing process: 5052 aluminum alloy contains 3-5% magnesium, and its crystal structure forms a uniform and dense oxide film in the electrolyte, achieving a tensile strength of 240 MPa and an elongation of 10-15%; 6061 aluminum alloy, through magnesium-silicon synergistic strengthening, can reach a hardness of 95 HB in the T6 temper, making it particularly suitable for applications requiring subsequent bending. Experimental data shows that in a 15 wt% sulfuric acid electrolyte, the porosity of the oxide film formed by 5052 aluminum alloy is 37% lower than that of 1060 pure aluminum, which directly improves the adsorption stability of black dyes. Tests conducted by an automotive parts manufacturer showed that black brushed aluminum sheet using 6061 substrate achieved 2000 hours of corrosion resistance in salt spray testing, extending their lifespan fivefold compared to traditional spray coating processes.

Regarding processing tempers, the black brushed anodized aluminum sheets are primarily available in O temper (annealed), T6 (air-cooled quenching + artificial aging), or H14 tempers. The O temper substrate has a hardness ≤30HB and an elongation ≥18%, suitable for complex forming scenarios requiring subsequent bending and stamping. The T6 temper substrate has a hardness of 80-100HB, tensile strength ≥205MPa, and yield strength ≥110MPa, making it more suitable for load-bearing or support components requiring structural strength. These brushed anodized aluminum sheets, after heat treatment and cold working, possess excellent mechanical properties, with tensile strength exceeding 310 MPa and yield strength around 275 MPa, exhibiting high strength and rigidity. This allows the black brushed anodized aluminum sheet to demonstrate superior performance under external pressure and impact.

The surface treatment process of the black brushed anodized aluminum sheet is a major highlight.

The essence of wire drawing is the process control of plastic deformation of the metal surface. We use an 8-axis CNC wire drawing machine imported from Germany, employing a 120-400 mesh diamond abrasive belt to directionally rub the aluminum sheet, forming straight or random textures with a depth of 0.02-0.1mm. The texture depth is controlled at 0.01-0.03mm, and the surface roughness Ra value is ≤0.8μm, which not only enhances the decorative texture but also strengthens surface adhesion.

The anodizing process utilizes dual-pulse power supply technology, maintaining a current density of 15±0.5A/dm² in an electrolyte at 18±1℃. The anodized film thickness is 10-20μm (customizable to 30μm according to corrosion resistance requirements). After sealing treatment, the film porosity is ≤5%, with salt spray corrosion resistance exceeding 1000 hours (neutral salt spray test GB/T 10125), and abrasion resistance ≥50 cycles (with a 500g load, no significant color fading after wiping with a cotton cloth). The black film layer is colored with environmentally friendly organic dyes, with a color difference ΔE ≤ 1.5 (CIE Lab standard). Anodized aluminum sheet exhibits excellent weather resistance, after 1000 hours of xenon lamp aging testing, the color difference ΔE ≤ 2.0, with no obvious fading or chalking. Furthermore, the black anodized aluminum sheet's surface resistivity is ≤ 10^8 Ω, providing basic anti-static properties, while maintaining a thermal conductivity of 180-200 W/(m·K), meeting heat dissipation requirements.

Based on these performance characteristics, the application scenarios for black brushed anodized aluminum sheets exhibit precision and high-end features.

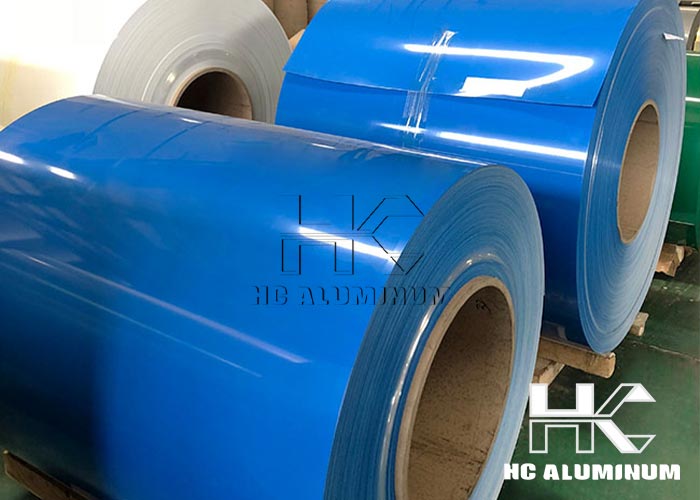

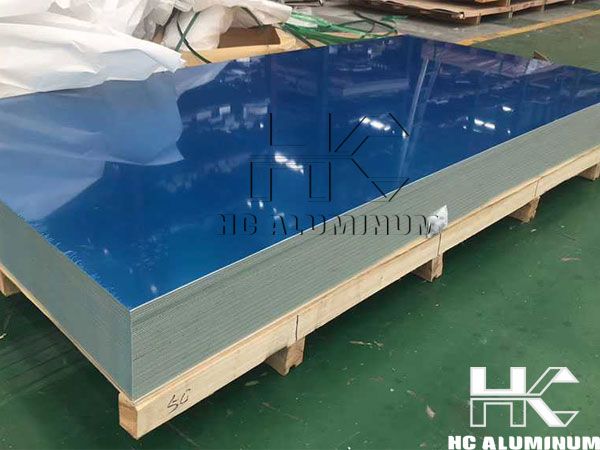

In the architectural decoration field, 1.5-2.5mm thick black brushed sheets are widely used in curtain wall decoration of high-end office buildings and hotels, elevator car panels, and door frame lines. Their weather resistance and decorative properties meet the requirements for a service life of over 15 years.

In the electronics and electrical appliance field, 0.8-1.2mm thick black brushed aluminum sheets are used in laptop shells, mobile phone frames, and speaker panels. Their anti-static and heat dissipation performance ensures the stable operation of electronic components.

In the precision manufacturing field, 3.0-5.0mm 6061 t6 black brushed anodized aluminum sheets are used in automated equipment guide rails and instrument housings. Their high strength and flatness meet the requirements of precision assembly.

Furthermore, brushed anodized aluminum sheet product is also used in automotive interior parts (such as center console panels) and medical device housings. With its environmentally friendly and non-toxic (RoHS compliant) advantages, it meets the stringent requirements of high-end manufacturing.

In summary, the core competitiveness of black brushed anodized aluminum sheets stems from precise alloy ratios, mature processing technology, and excellent comprehensive performance. We ensure product quality stability by strictly controlling the purity of the base material and optimizing the anodizing process parameters. At the same time, we can provide customized alloy states, thickness specifications and surface treatment solutions according to the individual needs of customers, helping them achieve a dual improvement in product performance and appearance.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531