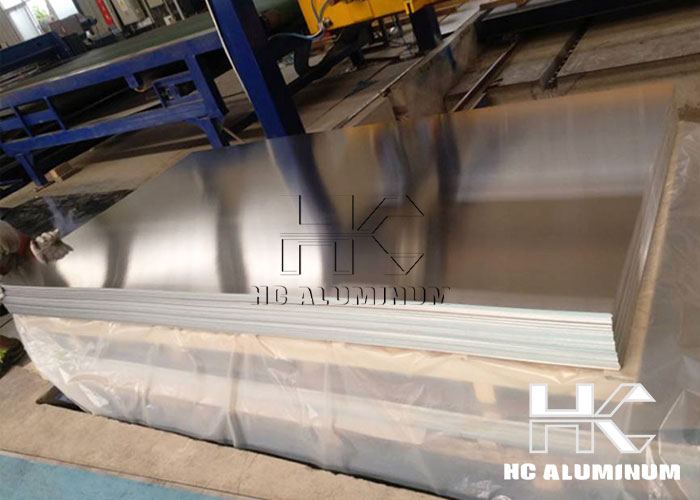

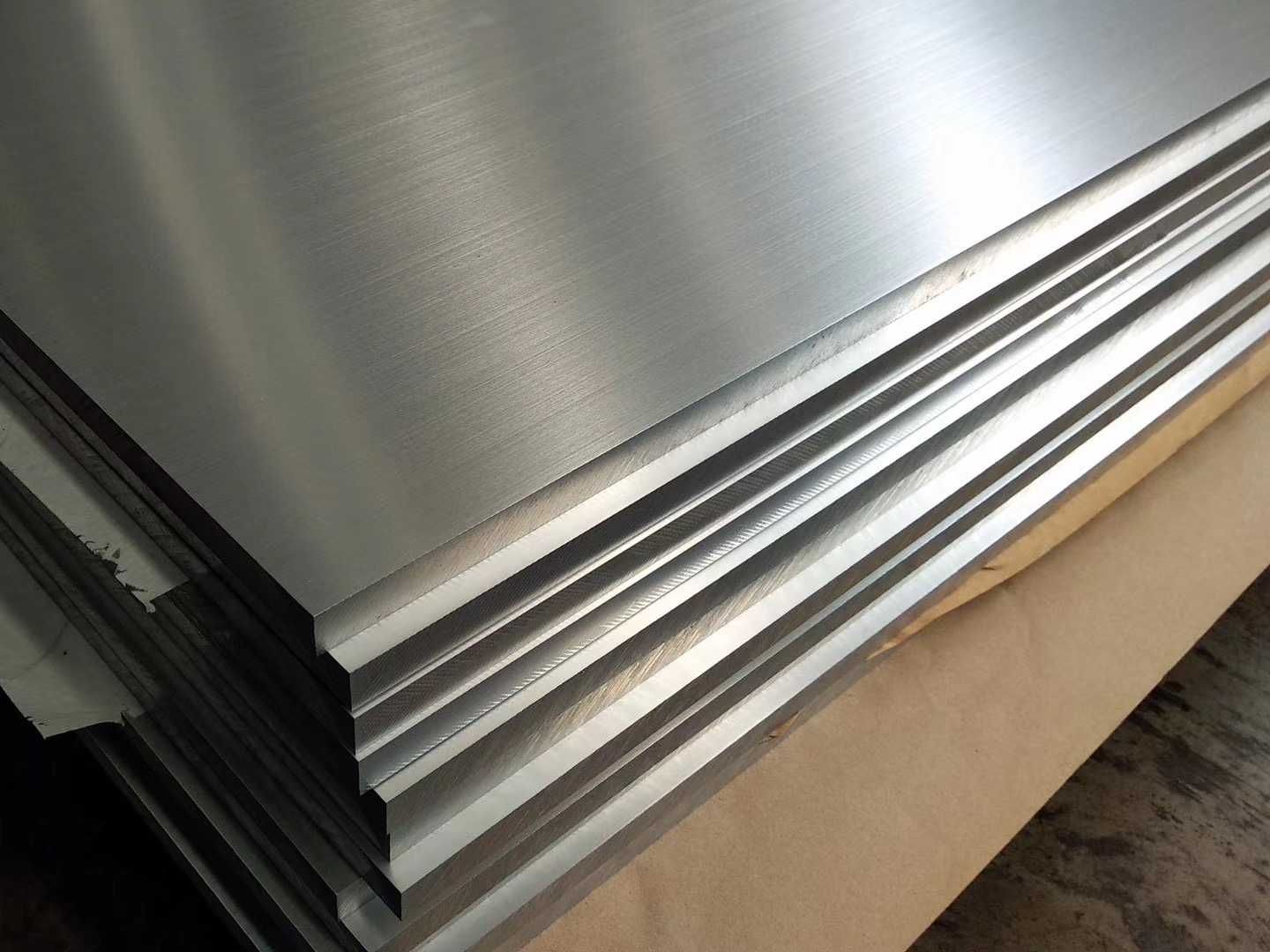

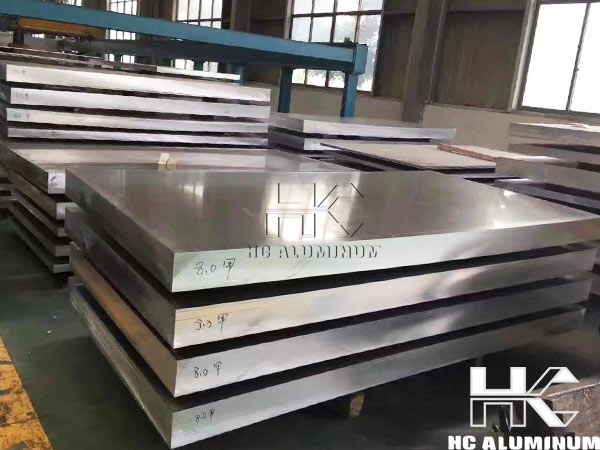

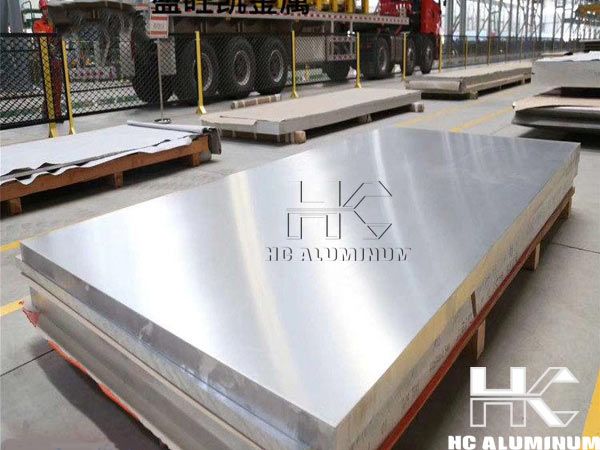

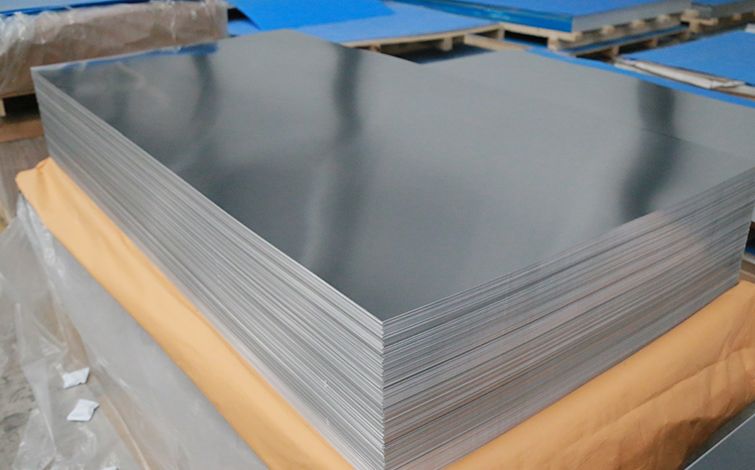

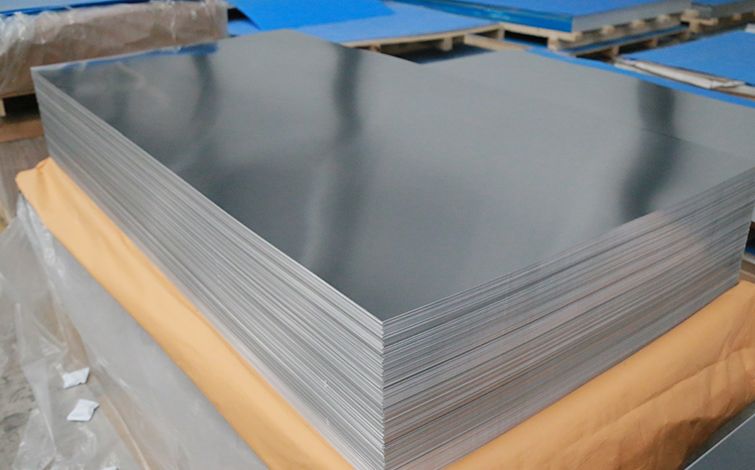

Rust-proof aluminum Sheet Plate

Rust-proof aluminum sheet is a type of aluminum alloy sheet with significantly enhanced corrosion resistance through alloying and surface treatment

Rust-proof aluminum sheet is a type of aluminum alloy sheet with significantly enhanced corrosion resistance through alloying and surface treatment. It is widely used in industrial applications requiring high weather resistance. Key aluminum alloy series for rust-proof aluminum sheet include 3003, 5052 and 6061, with 3003 and 5052 being the most commonly used. 3003 rust-proof aluminum plate is primarily composed of aluminum and manganese, the addition of manganese imparts excellent corrosion and oxidation resistance, making it particularly suitable for use in humid or corrosive environments.

Alloy system and performance characteristics of rust proof aluminum sheet

1. Al-Mn aluminum alloys (such as 3003 and 3A21)

- Economical: With a manganese content of 1.0%-1.7%, the cost is lower than that of Al-Mg alloys, making it suitable for cost-sensitive applications such as pipeline insulation and building curtain walls.

- Formability: Excellent ductility in the annealed state allows for deep drawing, making it commonly used in thin-walled containers such as fuel tanks and beverage cans.

2. Al-Mg alloys (such as 5052, 5A06, 5083 and 5086)

- Corrosion resistance: With a magnesium content of 2.2%-4.9%, 5052 aluminum sheet performs exceptionally well in marine climates and salt spray environments. For example, 5052 aluminum sheet can withstand over 1,000 hours of salt spray testing without significant corrosion.

- Strength: With a tensile strength of 230-280 MPa (5052), it is suitable for medium-load applications such as automotive structural parts and pressure vessels.

- Typical applications: Ship decks (5083), refrigerated truck bodies (5A06), and new energy battery module side panels (5083).

Features of rust-proof aluminum sheet:

- Excellent corrosion resistance:

Rust-proof aluminum plate performs exceptionally well in humid or corrosive environments, effectively resisting oxidation and corrosion and extending its service life.

- Lightweight and high-strength:

Aluminum alloys offer low density, light weight, and high strength, making them suitable for a variety of structural applications.

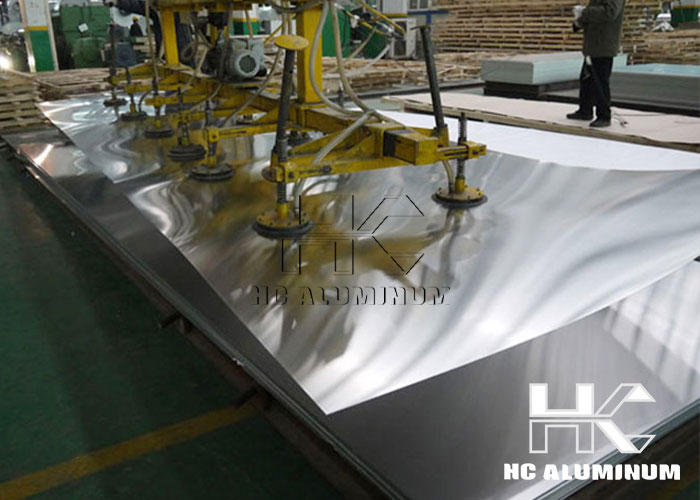

- Excellent Processability:

Rust-proof aluminum sheet is easy to cut, weld, and form, making it suitable for various manufacturing processes.

- Aesthetic Appearance:

Aluminum's smooth surface is easy to clean, making it suitable for decorative applications.

- Excellent Thermal and Electrical Conductivity:

Aluminum alloys offer excellent thermal and electrical conductivity, making them suitable for specific industrial applications.

Due to rust-proof aluminum sheet have so many advantages, the application range is extremely wide, take 3003 rust-proof aluminum plate as example, it is used in:

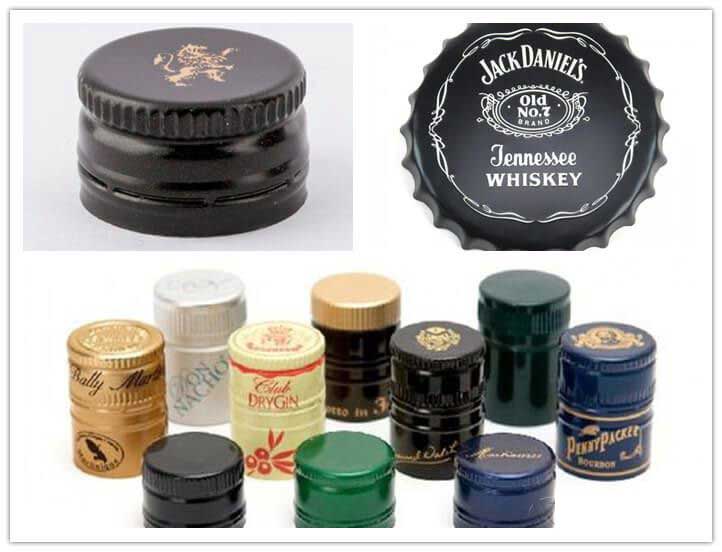

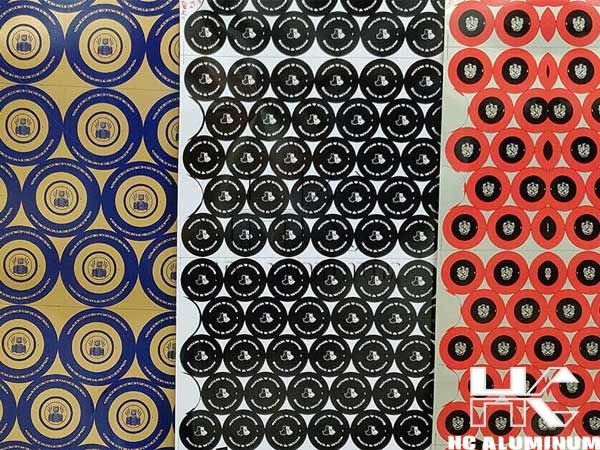

- Packaging and Containers

1. Food/Beverage Packaging

Applications: Cans, food storage containers, and liquid condiment storage tanks (such as soy sauce and vinegar jars).

Suitability: 3003 aluminum sheet offers excellent ductility (annealed elongation ≥20%) and can be deep-drawn into thin-walled containers (0.2-0.5mm thick). Its surface is easily passivated, meeting food contact safety standards (such as FDA and GB 4806.10) and resisting mild acid and alkali corrosion (stable in environments with a pH of 5-9).

2. Industrial Storage and Fuel Tanks

Applications: Automobile auxiliary fuel tanks, small lubricant tanks, and agricultural machinery hydraulic oil storage tanks. Suitable for: Excellent welding performance (argon arc weld strength reaches 85% of the base material), can be made into sealed containers, and offers some corrosion resistance to non-corrosive media such as gasoline and diesel. It is over 40% lighter than steel tanks.

- Construction and HVAC

1. Pipe Insulation and Ventilation Systems

Applications: Central air conditioning ventilation ducts, central heating duct cladding, cold storage insulation panels.

Suitable for: 3003 aluminum sheet offers a smooth surface (Ra ≤ 0.8μm), is easy to clean, and is resistant to humid indoor environments (no noticeable rust at relative humidity ≤ 90%). It also exhibits excellent compatibility with insulation materials such as polyurethane and rock wool. When processed into corrugated or flat sheets, it achieves a compressive strength exceeding 15MPa.

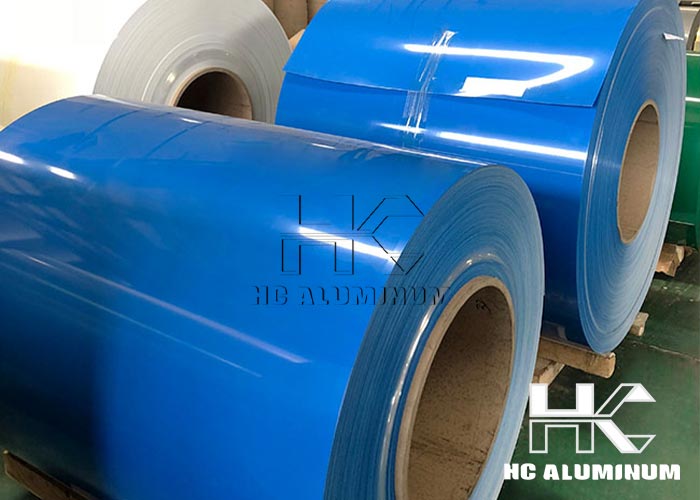

Specifications: Common thicknesses range from 0.3-1.0mm and widths from 1000-1500mm, making it suitable for continuous coil processing.

2. Architectural Decoration Materials

Applications: Curtain wall linings, ceiling keel covers, and interior partition trim strips.

Suitability: Lower cost than 5000 series aluminum alloys, and surface aesthetics can be enhanced through anodizing (producing a 5-10μm oxide film) or powder coating. Suitable for dry indoor environments (avoiding prolonged outdoor exposure to rain), offering a better price-performance ratio than stainless steel decorative panels.

- Transportation

1. Lightweight Vehicle Components

Applications: Truck/trailer side panels, refrigerated truck body panels, and electric tricycle floor panels.

Suitability: Moderate strength (tensile strength 110-145MPa), significant lightweight advantages (density 2.73g/cm³), a 60% weight reduction compared to steel, and reasonable corrosion resistance to road de-icing agents (low-concentration sodium chloride), making it suitable for urban and short-distance transport vehicles.

2. Rail Transit Accessories

Applications: Subway/light rail interior decorative panels (such as seat backs, luggage rack panels), and train vent grilles. Suitable for: No spark hazard (non-magnetic), meets rail transit fire protection standards (oxygen index ≥ 28), and is not prone to cracking when processed into special-shaped parts (no cracking when the cold bend radius is ≥ 1.5t).

- Chemical and Light Industry

1. Low-Corrosive Media Pipes

Applications: Pure water pipelines, dilute sulfuric acid (concentration ≤ 10%) pipelines, and electroplating wastewater pretreatment tanks.

Suitable for: In mildly corrosive environments (pH 4-10), its corrosion resistance is superior to that of pure aluminum sheet 1060, and its price is only 70% of that of 5052, making it suitable for low-cost retrofits for small and medium-sized chemical companies.

2. Light Industrial Products

Applications: Washing machine inner drums, water heater housings, and solar collector back panels.

Suitable for: Resistant to hot water corrosion (≤ 80°C), easy to stamp and form, and has good connectivity with materials such as plastics and rubber (can be fixed with rivets or adhesives).

The core value of 3003 rust-proof aluminum plate lies in its "balanced cost-effectiveness". It is particularly suitable for cost-sensitive scenarios with moderate corrosion resistance requirements and complex forming requirements. It is one of the mainstream choices in the industrial field to replace steel plates and pure aluminum plates.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531