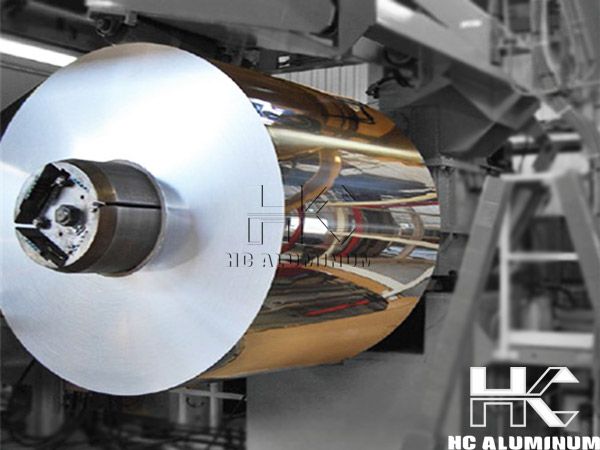

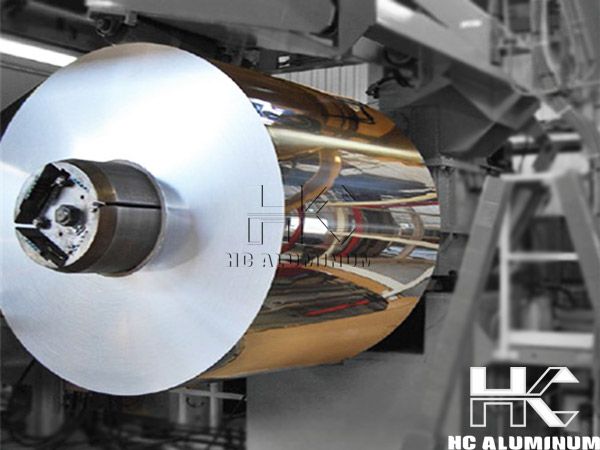

Mirror Polished Aluminum Sheet For Solar Reflector

Mirror polished aluminum sheets, as the core material for solar reflectors, excel in the field of solar thermal utilization due to their high reflectivity, weather resistance, and processing performance.

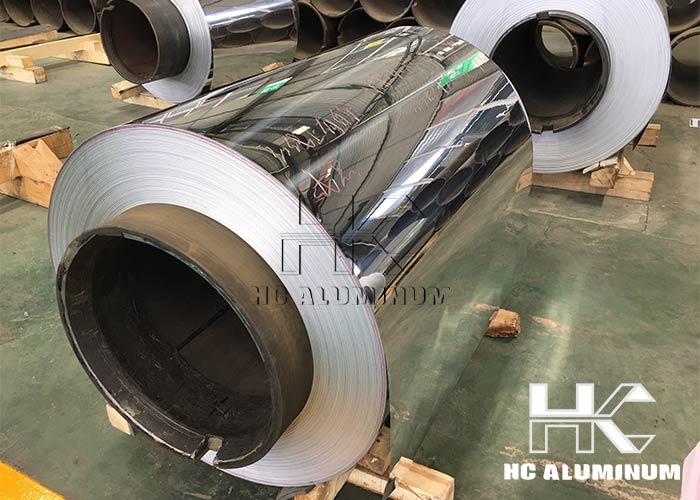

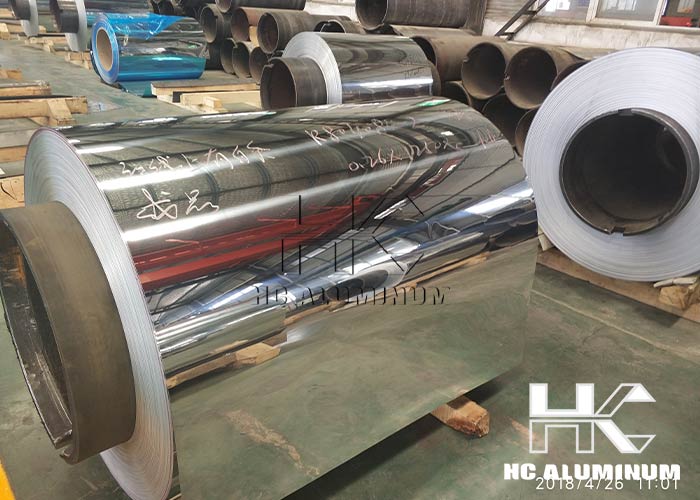

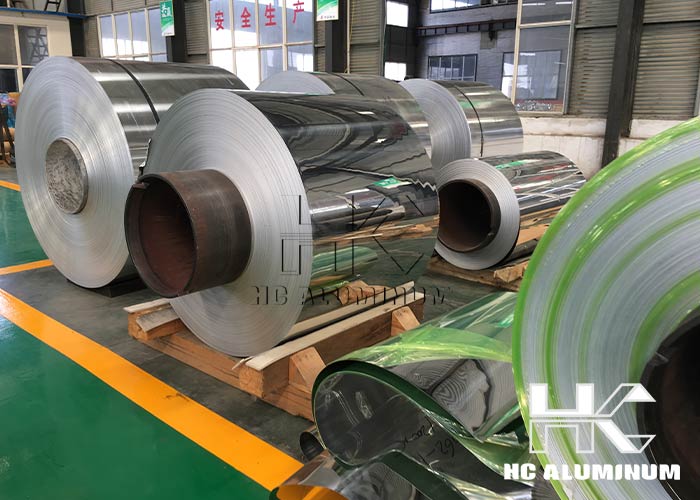

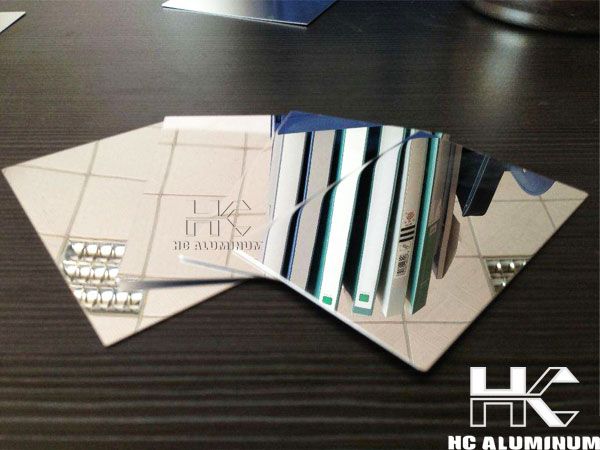

Mirror polished aluminum sheets, as the core material for solar reflectors, excel in the field of solar thermal utilization due to their high reflectivity, weather resistance, and processing performance. They are commonly used in solar reflectors, optical equipment, and other applications requiring high reflectivity.

Common materials of mirror polished aluminum sheet for solar reflector:

- 1060 Pure Aluminum:

Containing over 99.6% aluminum, it possesses excellent elongation and tensile strength, suitable for complex processing such as stamping and stretching. Its high reflectivity makes it an ideal material for solar reflectors, including solar collectors.

- 5052/6061 Aluminum Alloy:

Belonging to aluminum-magnesium alloys, it has low density, high strength, and strong corrosion resistance. Besides solar reflectors, it is also suitable for automotive interiors, aerospace components, and other applications requiring high material performance.

Processing methods of mirror polished aluminum sheet:

- Mechanical polishing:

Using polishing equipment and abrasives to treat the aluminum sheet surface through mechanical grinding, removing surface imperfections and unevenness to achieve a mirror finish.

- Chemical polishing:

Using chemical agents to corrode and dissolve the aluminum sheet surface to obtain a smooth, mirror-like surface. Suitable for aluminum alloys with relatively low hardness.

- Anodizing:

An anodized film is formed on the polished aluminum sheet surface, which not only improves corrosion resistance but also further enhances reflectivity and appearance.

Performance advantages of mirror polished aluminum sheet for solar reflector:

- High reflectivity:

Mirror finish aluminum sheets, processed through rolling, polishing, or anodizing, achieve a reflectivity of 86%~98%.

Ordinary mirror polished aluminum sheets: Reflectivity approximately 86%, suitable for general solar thermal applications;

Super mirror polished aluminum sheets: Reflectivity as high as 95%~98%, designed specifically for high-reflectivity outdoor applications, maximizing the concentration of solar radiation.

- Weather resistance and stability:

After surface treatment with oxidation or nano-composite coatings, the surface possesses UV resistance, heat resistance, and corrosion resistance, suitable for long-term outdoor use (e.g., CPC composite parabolic concentrator systems, parabolic trough concentrators CSP).

- Lightweight and processable:

Aluminum sheets come in a wide thickness range (0.05~50mm), allowing for curved surface design to reduce image distortion and adapting to complex concentrating structures such as parabolic troughs and linear Fresnel arrays.

Supports production in roll or sheet form, facilitating large-scale application in solar thermal power plants and medium-to-high temperature solar thermal utilization projects.

Application scenarios of mirror polished aluminum sheet:

1. Solar thermal power generation systems

- Parabolic trough system:

Mirror aluminum sheets act as reflectors, focusing sunlight onto collector tubes along the focal line. This heats the heat transfer fluid (such as synthetic oil) to generate steam, driving a turbine generator.

- Tower system:

Mirror reflective aluminum plates in the heliostat array reflect sunlight to the receiver at the top of the tower, supporting 200MW-level power output.

- Dish system:

Dual-axis tracking dish reflectors using mirror polished aluminum sheets achieve power generation efficiencies up to 30%, suitable for distributed applications.

2. Solar thermal collection and heating

- CPC solar collectors:

Mirror aluminum sheet refocus and diffusely reflect sunlight, increasing the collection temperature to 100-600℃, suitable for medium- and high-temperature applications such as solar air conditioning and boilers.

- Building integrated photovoltaics (BIPV):

Mirror reflective aluminum sheets serve as building facade materials, replacing traditional glass curtain walls, reflecting sunlight while reducing energy consumption.

3. Special applications

- Space powered solar satellites (SPS):

Lightweight mirror finish aluminum sheets reflect sunlight to a ground receiving station, converting it into electricity which is then transmitted via microwaves.

- Solar cookware and solar observators:

Mirror aluminum sheets focus sunlight to achieve fuel-free cooking or stable lighting.

Mirror polished aluminum sheets have wide applications in many fields, especially in renewable energy and high-efficiency lighting. With technological advancements, their application prospects will become even broader.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531