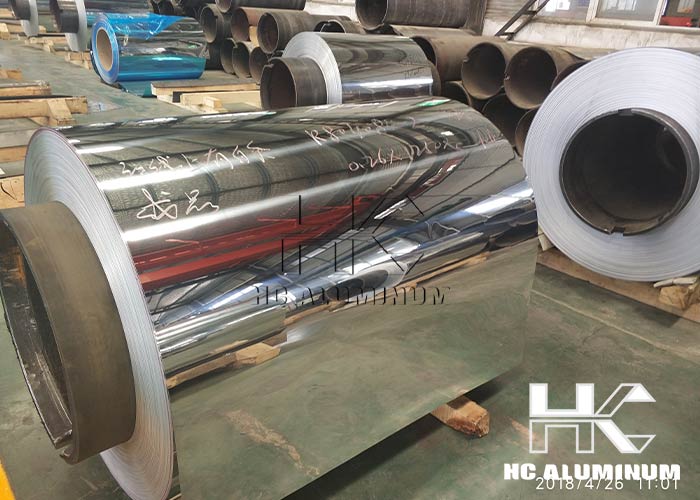

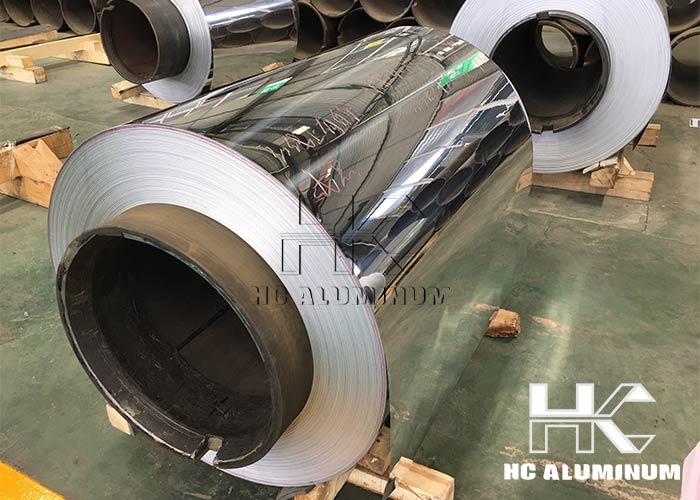

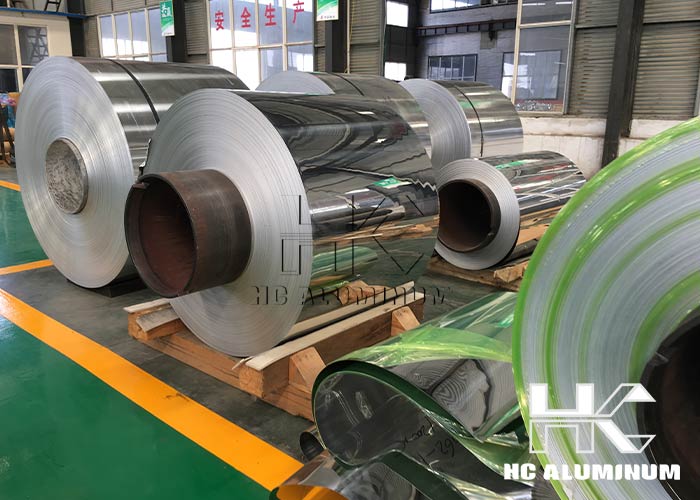

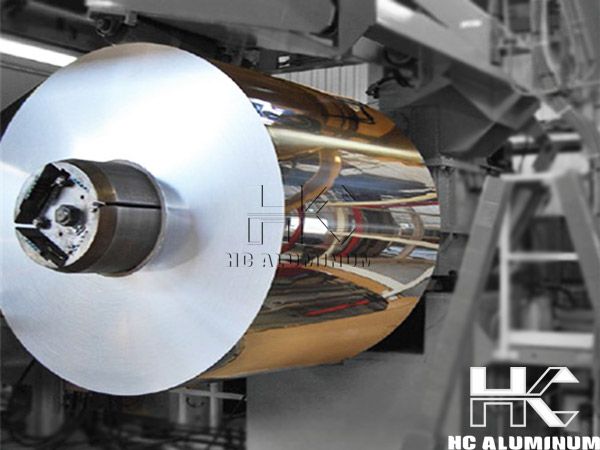

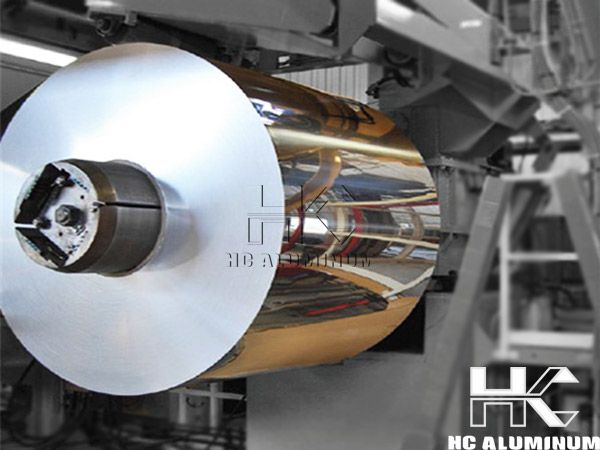

Mirror Aluminum Sheet Coil For Light Reflector

Mirror aluminum sheets, with their unique physical properties and precision manufacturing processes, are gradually becoming the preferred material for high-end lighting reflectors.

In the lighting industry, luminaire efficiency and light utilization remain core pain points. Traditional reflective materials, due to their high absorption rate and uncontrollable reflection direction, result in nearly half of the light emitted by the light source being ineffectively lost. Mirror aluminum sheets, with their unique physical properties and precision manufacturing processes, are gradually becoming the preferred material for high-end lighting reflectors.

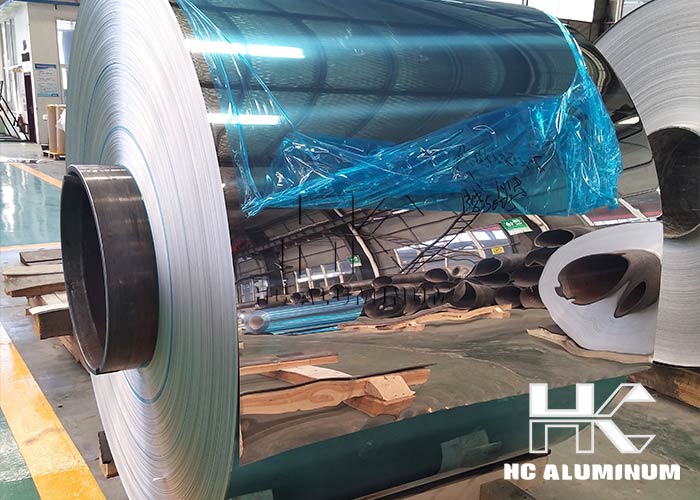

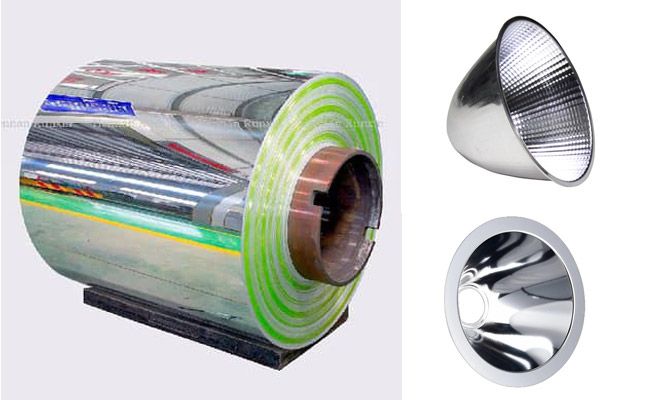

Mirror aluminum sheet for light reflector use high-purity aluminum (such as 1050 and 1070 series) or aluminum-magnesium alloys (5xxx series) as the base material, forming a mirror-reflective layer through continuous casting and rolling, ultra-precision polishing, and anodizing. We offer a full range of mirror-finish aluminum sheets in thicknesses from 0.05mm to 50mm and widths from 10mm to 1250mm, supporting both aluminum coil and aluminum sheet forms.

The core characteristics of mirror aluminum sheets include:

Ultra-high reflectivity:

High-end mirror aluminum sheet products can achieve a reflectivity of up to 95% (compared to 86% for standard grades), nearly double that of traditional stainless steel (50-60%). This means it can effectively reflect light emitted by the light source to the area requiring illumination, maximizing light efficiency. For example, after a certain international brand of LED downlights adopted our mirrored aluminum reflectors, its luminous efficacy increased by 23%, and the luminaire efficiency exceeded 85%.

Directional reflection accuracy:

Surface roughness Ra≤0.02μm ensures that light is reflected strictly according to the angle of incidence, avoiding the light energy dispersion caused by diffuse reflection in traditional frosted aluminum. In a rotating parabolic reflector, mirrored aluminum can concentrate 92% of the luminous flux emitted by the light source onto the target area, while frosted aluminum can only control 65%.

Weather resistance:

Mirror aluminum sheets can resist UV radiation and salt spray corrosion, with a service life exceeding 15 years in outdoor lighting fixtures. Aluminum itself has excellent oxidation resistance, and our advanced surface treatment technology during production forms a dense oxide film on its surface. This oxide film not only enhances the corrosion resistance of the aluminum mirror sheet but also improves its wear resistance, ensuring consistent reflector performance under various environmental conditions. This characteristic is particularly important, especially in harsh environments such as industrial lighting and outdoor lighting, effectively extending the lifespan of the luminaire. Actual testing of a tunnel lighting project showed that after 5 years of use, the reflectivity attenuation rate was less than 3%, far lower than the 15% attenuation of silver-plated reflectors.

The lightweight nature of mirror reflective aluminum sheets is also a major advantage in lighting design. Compared to traditional materials, aluminum has a lower density, reducing the overall weight of the lighting fixture. This not only facilitates transportation and installation but also reduces the requirements for supporting structures, increasing design flexibility. In terms of processing performance, mirror aluminum sheets have good plasticity and weldability, adapting to various complex lighting design needs. Whether stamping, bending, or laser cutting, our aluminum sheets maintain excellent surface finish and reflectivity, ensuring high-quality finished products. Furthermore, our production processes strictly adhere to the ISO9001 quality management system, ensuring that every batch of products meets high quality standards.

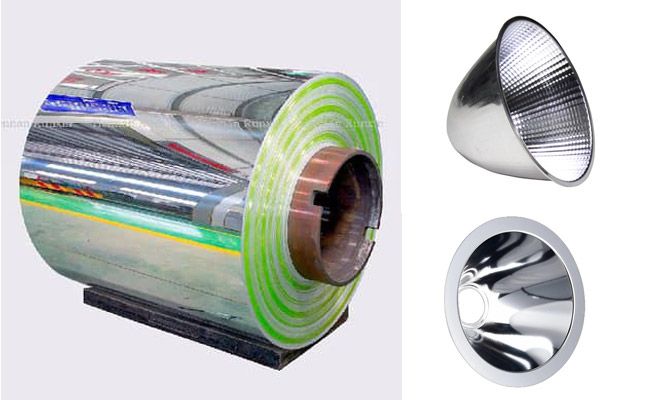

Typical application scenarios of mirror aluminum sheet used for lighting are:

Commercial lighting:

In high-illuminance scenarios such as grille lights and downlights, mirrored aluminum reflectors can increase luminous efficacy to over 120 lm/W. Statistics from a chain supermarket project show that replacing reflectors with mirrored aluminum reflectors reduced annual power consumption by 31% and extended the maintenance cycle to 5 years.

Industrial lighting:

In the high-temperature, high-humidity steel mill workshops, anodized mirrored aluminum reflectors withstood the dual tests of 85℃ high temperature and 95% humidity, with no oxide film peeling observed within 5 years.

Specialty lighting:

A deep-sea exploration light using 5052 alloy mirrored aluminum reflectors maintained structural integrity under the high pressure environment of a 2000-meter deep sea, with a reflectivity attenuation rate of <0.5%/year.

The advantages of mirrored aluminum reflectors in lighting fixtures are obvious. With their high reflectivity, excellent corrosion resistance, lightweight properties, superior processing performance, and environmental friendliness, our mirror aluminum sheet for light reflector can provide customers with efficient and reliable lighting solutions. We look forward to cooperating with more lighting manufacturers to jointly promote the development and innovation of the lighting industry.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531