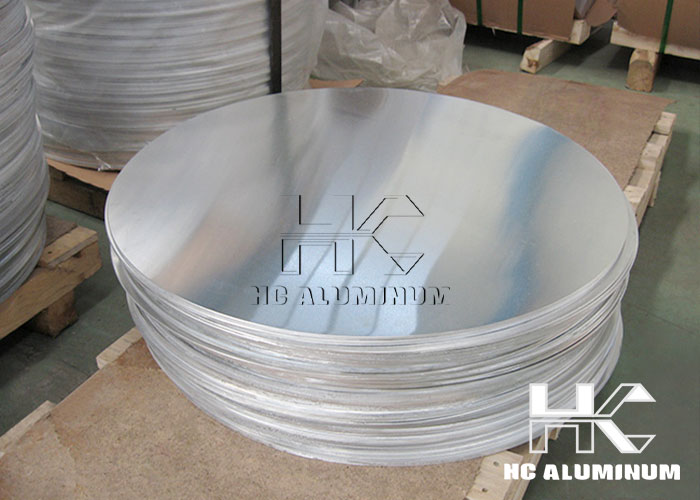

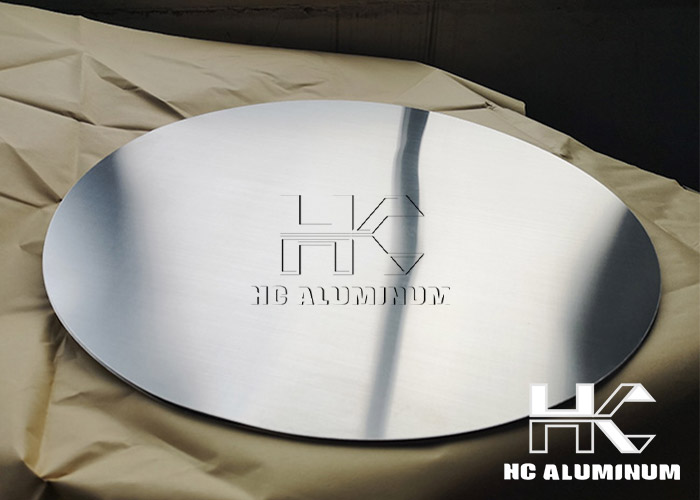

Aluminum Disc Circle For Spinning

Aluminum circles for spinning are those that meet the requirements of the spinning process in terms of material quality, mechanical properties, surface quality and specifications.

Spinning is a metalworking process used to form aluminum circles into various shapes, such as pots, lamps and utensils, through rotation and pressure. Aluminum circles for spinning are those that meet the requirements of the spinning process in terms of material quality, mechanical properties, surface quality, and specifications, enabling smooth forming and guaranteed quality of the finished product.

- Material:

Commonly used are pure aluminum grades such as 1050, 1060, 1070, and 1100, as well as aluminum-manganese alloys such as 3003, 3004, 3005 and 3105.

1060 aluminum circles offer excellent formability and corrosion resistance, are relatively affordable, and are widely used.

3003 aluminum circles are slightly stronger than pure aluminum, offer better corrosion resistance and processability, and are also commonly used in spinning.

- Tempers:

Commonly used are O (soft), H12, and H14.

Aluminum discs in the O state have good plasticity and are easy to spin-form, but they have lower strength.

Semi-hard aluminum discs such as H12 and H14 maintain a certain degree of plasticity while possessing higher strength, allowing them to better maintain their shape and dimensional accuracy after spinning.

- Specifications:

Thickness generally ranges from 0.5mm to 6mm, and diameters range from 100mm to 1200mm. However, different manufacturers can provide non-standard sizes of aluminum discs according to customer needs, customizing them through mold creation.

- Performance Requirements:

To ensure high-quality spinning, aluminum circles must exhibit good tensile strength and plasticity. The surface should be flat and smooth, free of scratches, oil stains, oxidation, and other defects. The edges should be neat and burr-free. They also need to exhibit good deep-drawing and spinning properties, with an elongation of 30%-35% and a first-grade grain size. These properties are crucial for avoiding defects such as orange peel, square edges, and ruffles that can occur during spinning.

Characteristics of aluminum circle for spinning:

- Good Plasticity:

Aluminum alloys suitable for spinning should exhibit good ductility to prevent cracking or uneven deformation during the spinning process.

- Moderate Strength:

The aluminum alloy should be strong enough to support the stresses generated during processing while not being too rigid to be difficult to machine.

- Good Weldability and Machinability:

In some cases, welding or further processing may be required after spinning, so the material's weldability and machinability are also important considerations.

- Surface Quality:

The surface of the aluminum disc should be smooth to reduce friction during spinning and improve the surface quality of the finished product.

Selection Recommendations

For general containers, lampshades, and decorative parts: 3003-O aluminum discs are recommended for their cost-effectiveness and excellent formability.

For high-strength structural parts: 5052-O or 6061-O can be considered (hot spinning may be required).

For applications requiring high corrosion resistance: 5052 is preferred.

For simple forming or minimal strength requirements: 1100-O can be used.

The core of aluminum discs for spinning is "plasticity that meets standards, strength that is suitable, and stable quality" - they must have sufficient plasticity to cope with deformation, and be able to select materials with appropriate strength according to product requirements, while ensuring specification accuracy and surface quality to successfully complete the spinning process and ensure the performance of the finished product.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531