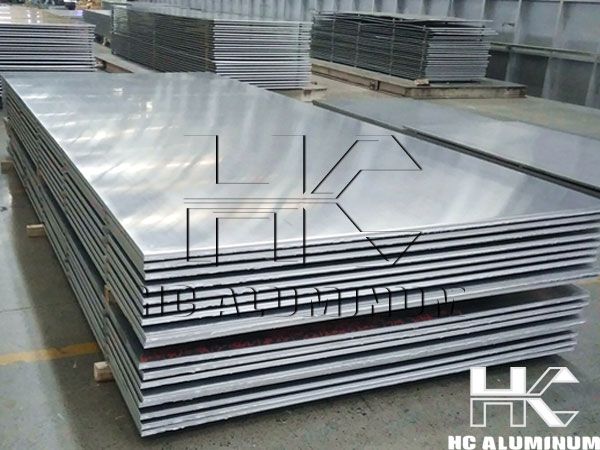

5083 H32 Aluminum Plate

5083 H32 aluminum plate have evolve from a specialized material for the shipbuilding industry to a benchmark product across multiple sectors.

As a technical engineer with over a decade of experience in aluminum plate manufacturing, I have witnessed the entire process of 5083 H32 aluminum plate evolving from a specialized material for the shipbuilding industry to a benchmark product across multiple sectors. This 5xxx series aluminum alloy, with magnesium as its primary alloying element, is sparking a materials revolution in the global high-end manufacturing sector thanks to its unique H32 stabilization treatment.

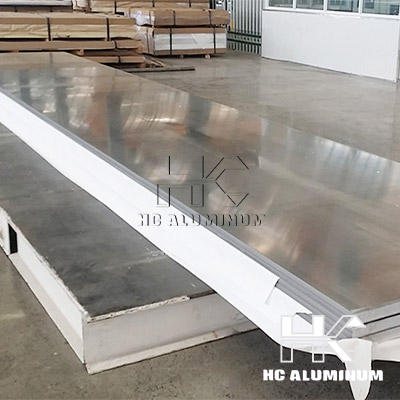

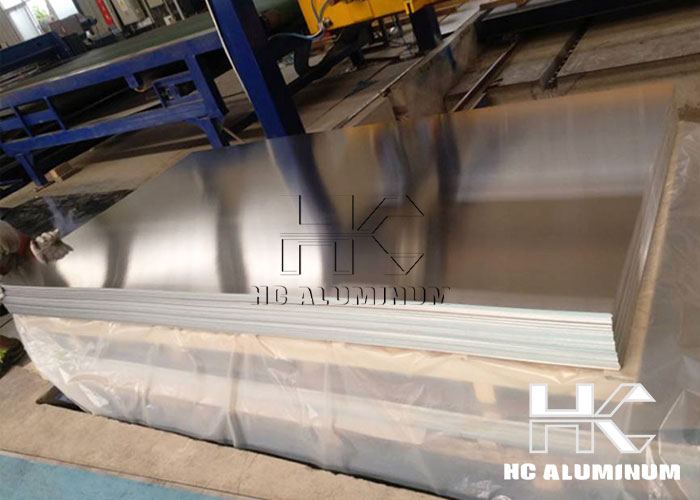

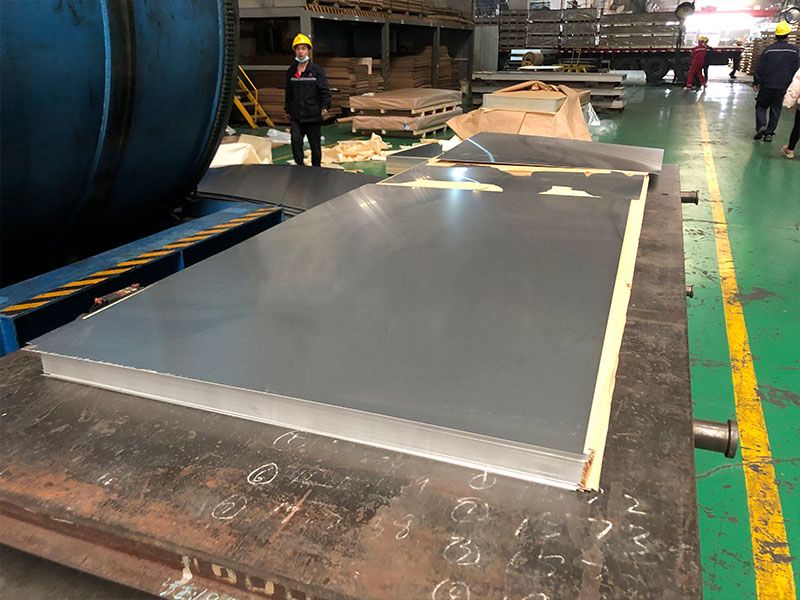

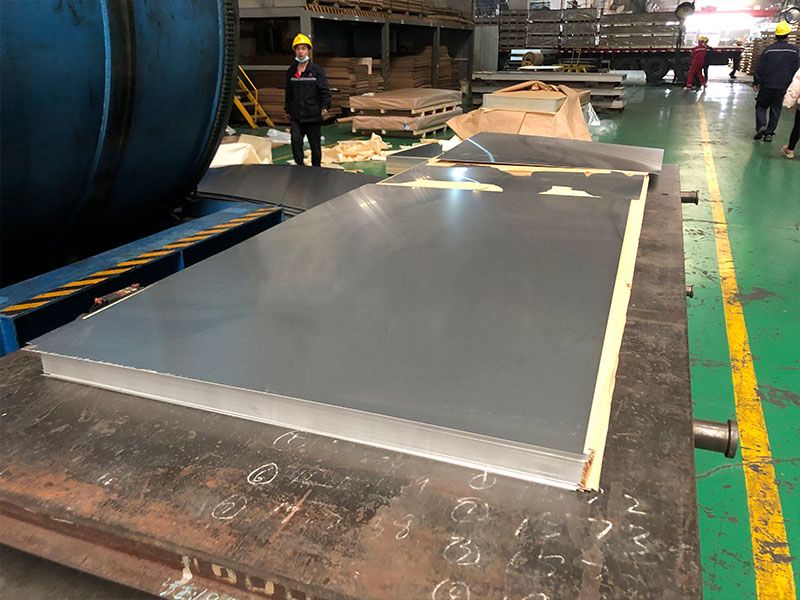

HC Aluminum's 5083 H32 aluminum plate offers a complete specification matrix: thicknesses ranging from 0.5mm to 150mm, widths up to 3200mm, and lengths customizable up to 12000mm. For shipbuilding needs, we have developed ultra-wide hull plates measuring 12×2000×8000mm, with tolerances controlled within ±0.02mm. Combined with precision processes such as laser cutting and waterjet machining, seamless splicing of complex hull structures can be achieved. A Norwegian icebreaker project used our H32 aluminum plates to manufacture the hull. In extreme cold environments of -30°C, the dynamic load-bearing capacity was increased by 25% compared to traditional marine steel, verifying the material's reliability under extreme conditions.

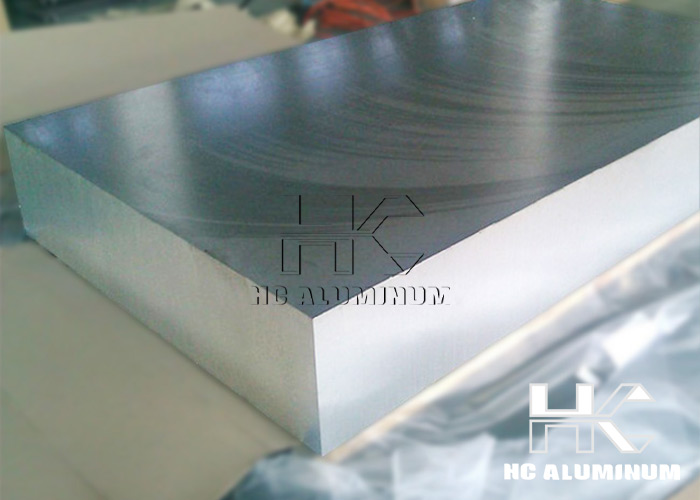

The H32 temper, through cold rolling and partial annealing processes, gives the material both strength and toughness. Actual test data shows: tensile strength reaches 275-350 MPa, yield strength 210 MPa, elongation 16%, and a minimum bending radius of only 1.5 times the plate thickness. In a marine platform project, the fatigue life of key nodes on laser-shock-strengthened H32 aluminum plates was extended by 3 times, successfully withstanding the impact of a category 12 typhoon.

Regarding corrosion resistance, the salt spray corrosion rate of 5083 H32 aluminum plate in 3.5% NaCl solution is less than 0.03 mm/year. Combined with fluorocarbon coating technology, the protective life can reach more than 10 years. An LNG carrier using our coating solution achieved a fatigue crack propagation rate of only 0.02 mm/1000 cycles in the weld area after 20,000 hours of service, a 60% reduction compared to traditional materials.

Furthermore, 5083 H32 aluminum plate exhibits excellent machinability, is easy to weld and cut, and can adapt to various complex processing techniques. Its good plasticity prevents cracking during forming, ensuring product integrity and service life.

In the shipbuilding sector, 5083 aluminum plate holds a 62% global market share in marine aluminum alloys, widely used in core components such as liquefied natural gas storage tanks, icebreaker hulls, and cruise ship superstructures. In the rail transit industry, its low density reduces subway car weight by 30% and energy consumption by 18%. In the aerospace field, a space fuel storage tank using H32 aluminum plate achieves safe liquid hydrogen storage, maintaining an impact energy of 22J even at -196℃ liquid nitrogen temperatures.

The price of 5083 H32 aluminum plate is influenced by various factors, including raw material costs, market demand, processing technology, and order volume. Generally, the current market price range for 5083 H32 aluminum plate is $3.8-5.2/kg. However, HC Aluminum has achieved a value leap through material optimization: the 5083-SC alloy developed using microalloying technology increases the yield strength to 280MPa while maintaining an elongation of 12%, reducing the amount of aluminum used in a single ship hull structure by 15%. In a container ship project, the use of dual-wire MIG welding reduced the width of the weld softening zone to 5mm, decreased the need for straightening processes, and lowered overall costs by 22%.

As a materials engineer, I firmly believe that true technological value lies not in playing with numbers on a parameter table, but in helping clients build end-to-end solutions from design optimization to operation and maintenance management. HC Aluminum's 5083 H32 aluminum plate is a concrete manifestation of this technological philosophy in the metal world—it is not only a cold industrial material, but also an engineering language that connects the present with the future, and land with the sea.

TABLE OF Contents

HENAN HC ALUMINUM CO., LTD

Tel: +86-371-58525958

Email: sales@aluhc.com

Website: https://www.aluhc.com

OFFICE ADDRESS: 1107, Lujin Building, CBD, ZHENGHZOU, HENAN CHINA

CONTACT: MR. MA

CELL/Whatsapp: 008618137889531